Electron beam technology can also be used for drilling and perforation in a micro range. This process is called electron beam drilling (EB drilling) or micro perforation. In this process, a focused electron beam is used to create precise holes in thin materials, typically with a thickness of less than 50 µm.

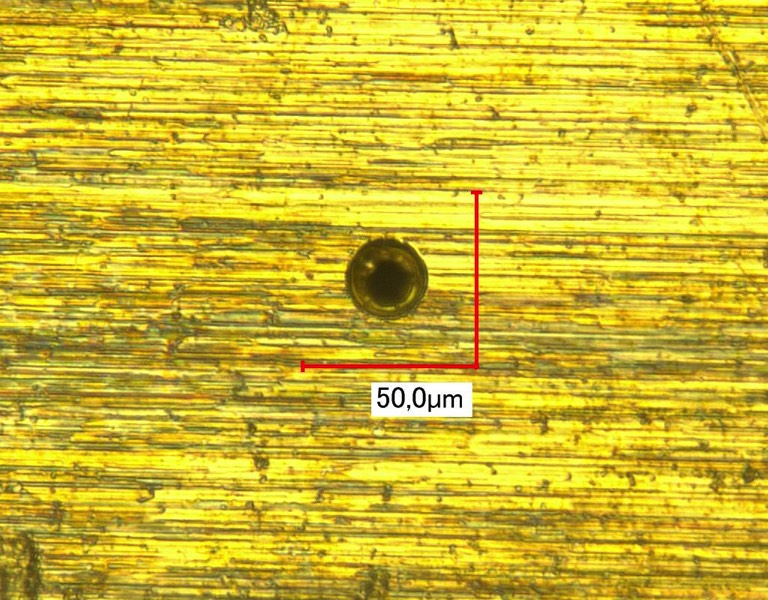

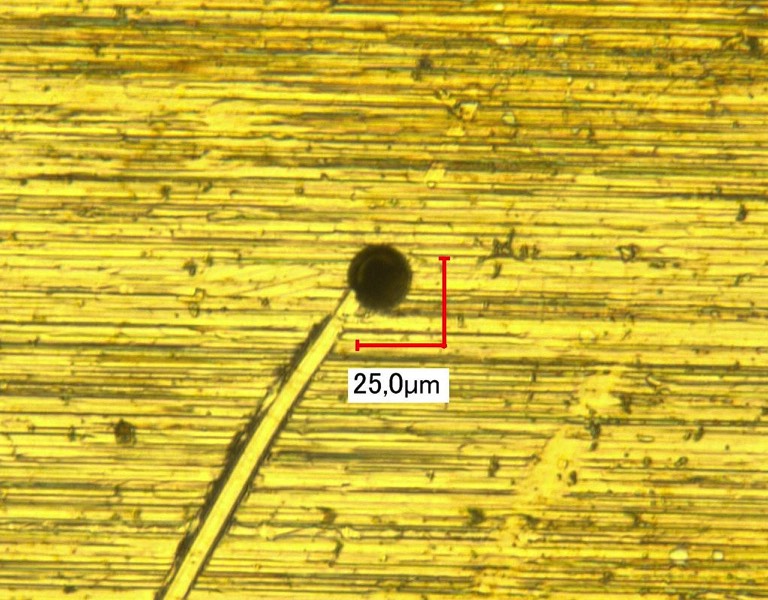

The key advantage of EB drilling is its ability to create high-quality and precise holes with a diameter as small as a few microns. The process can also be performed without the need for contact with the material, which eliminates the risk of damage or contamination. FOCUS electron beam welding machines use a highly focused electron beam (spot size below 50 µm), which allows for precise control over the drilling process. This makes it possible to create holes with diameters as small as a few microns (depends on the thickness of the parts), with a high level of accuracy and repeatability.

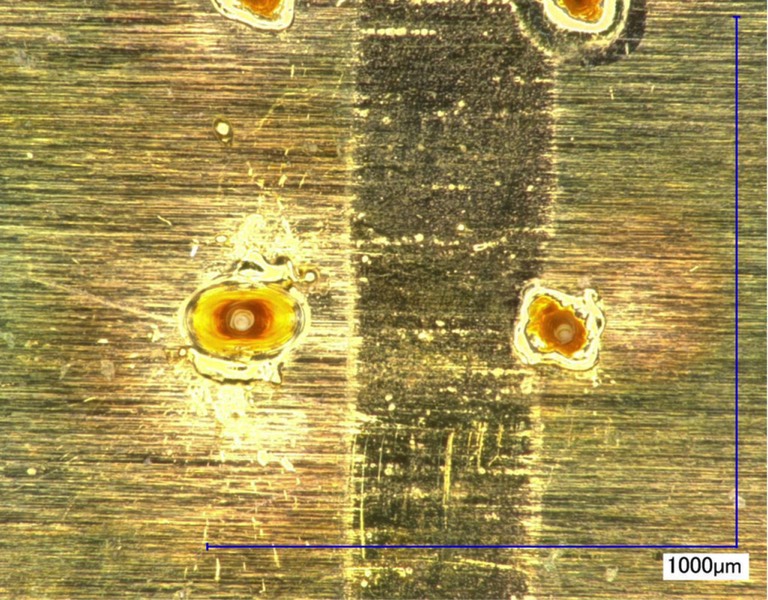

EB-Drilling with a pulsed beam. Due to the high intensity and the material independent absorption very delicate holes with less than 50 µm are achievable in every metal. The picture below shows drilling in a 500 µm thick gold metal sheet.