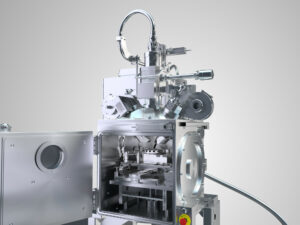

Best performance for axial & radial electron beam welding.

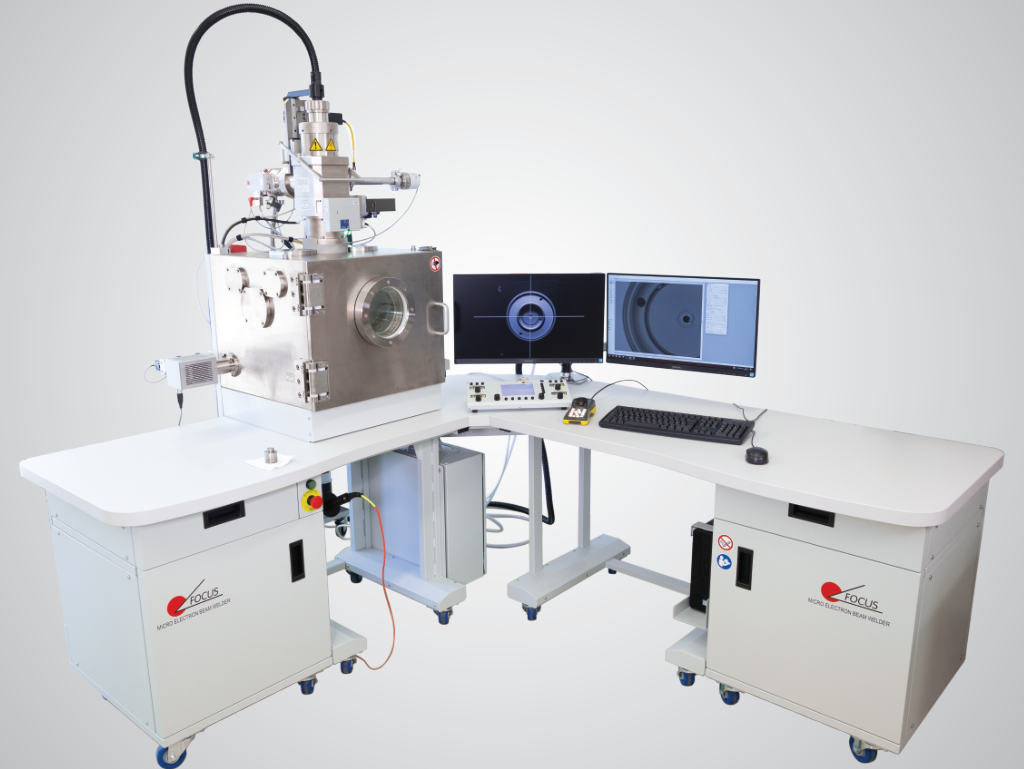

Compact electron beam welding machine with X/Y coordinate table.

Universal machine for a wide range

of EB welding tasks.

Customized electron beam welding machines with individual design.

Unique Electron beam generator with precise beam control.

Downloads

Welding Samples

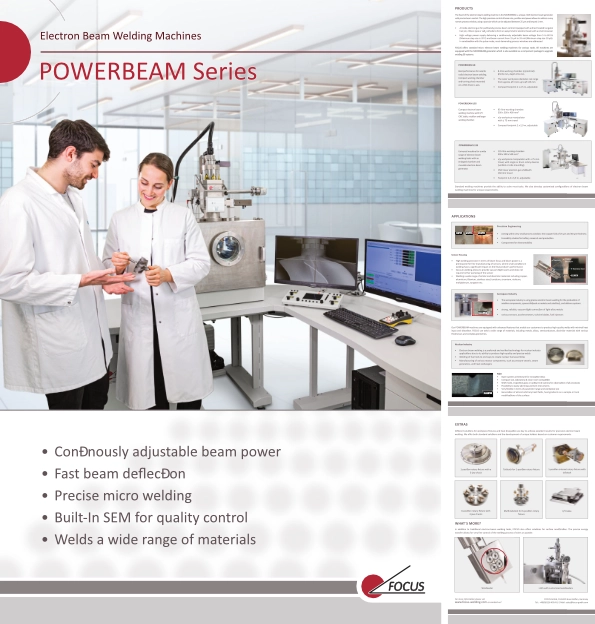

Introduction of the POWERBEAM Series

Please accept YouTube cookies to play this video. By accepting you will be accessing content from YouTube, a service provided by an external third party.

If you accept this notice, your choice will be saved and the page will refresh.

Specifications

Comparison of our standard electron beam welding machines

| POWERBEAM L8 | POWERBEAM L95 | POWERBEAM L135 | |

| Accelerating voltage | between 5 to 60 kV continuously adjustable | between 5 to 60 kV continuously adjustable | between 5 to 60 kV continuously adjustable |

| Maximum Beam current | 0.015 mA – 33 mA @ 60 kV, min step width 15µA, DC and fast pulse mode, min pulse width 10µsec | 0.015 mA – 33 mA @ 60 kV, min step width 15µA, DC and fast pulse mode, min pulse width 10µsec | 0.015 mA – 33 mA @ 60 kV, min step width 15µA, DC and fast pulse mode, min pulse width 10µsec |

| Beam power | 2 kW | 2 kW | 2 kW |

| Beam diameter @ 1mA | < 50 μm | < 50 μm | < 50 μm |

| Maximum beam deflection angle | ±8° | ±8° | ±8° (depending on deflection system) |

| Working chamber dimension | Ø235 mm x 200 mm | 500 x 500 x 400 mm ³ | 500 x 500 x 540 mm ³ |

| Work piece dimension | Ø100 mm x 150 mm | 250 x 230 x 170 mm³ | 250 x 230 x 170 mm³ |

| Workpiece handling | Linear/rotary manipulator | x/y CNC table with internal rotary device (tilting as option) | x/y CNC table with internal rotary device (tilting as option) CNC single or six-drum rotary motion manipulator CNC linear egun slide |

| Travel speed | 0.1 to 100 mm/s | 0.1 to 100 mm/s | 0.1 to 100 mm/s (x/y CNC table) 0.1 to 10 mm/s (CNC linear egun slide) |

| Rotary speed | from 0.1 to 1000 rpm continuously adjustable | from 0.1 to 100 rpm continuously adjustable | from 0.1 to 30 rpm continuously adjustable (CNC single or six-drum rotary motion manipulator) |

| Position accuracy | < 30 µm | < 30 µm | < 30 µm |

| SEM image resolution | down to approx. 25 μm | down to approx. 25 μm | down to approx. 25 μm |

| Pump down time | approx. 2 minutes | approx. 3 minutes | approx. 3 minutes |

| Foot print | 2 m x 2 m (angled setup) or 1 m x 3 m (straight setup) | 2 m x 2 m (angled setup) or 1 m x 3 m (straight setup) | 2.3 m x 3.9 m (angled setup incl. rack) or 1 m x 3 m (straight setup) |

| Power Supply | 230 V / 3.6 kW, single phase | 400 V / 4.6 kW, triple phase | 400 V / 4.6 up to 10 kW, triple phase (depending on configuration) |

| Gross Weight | approx. 350 kg | approx. 750 kg | approx. 1500 kg |